Zinare na nutsewa yana amfani da hanyar saka sinadarai, ta hanyar sinadari redox dauki hanyar samar da wani Layer na plating, gabaɗaya mai kauri, hanya ce ta sinadari na nickel zinariya Layer ajiya, zai iya cimma wani kauri na zinariya.

Gilashin zinari yana amfani da ka'idar electrolysis, wanda kuma ake kira hanyar electroplating. Yawancin sauran magungunan saman ƙarfe kuma ana amfani da su shine hanyar lantarki.

A cikin ainihin samfurin aikace-aikacen, kashi 90% na farantin zinare an nutsar da farantin zinare, saboda ƙarancin walƙiya na farantin zinare shine aibinsa mai mutuwa, amma kuma yana haifar da kamfanoni da yawa don ba da zinare- plated yi shi ne kai tsaye dalilin.

| Dukiya | Bayyanar | Weldability | Watsawar sigina | inganci |

| Lambun Zinare | Zinare mai farin | Sauƙaƙe wani lokacin walda mara kyau | Tasirin fata bai dace da watsa sigina masu tsayi ba | Juriyar walda ba ta da ƙarfi |

| PCB Immersion Zinariya | Zinare | Yayi kyau sosai | Babu tasiri akan watsa sigina | Ƙarfin juriya na walda |

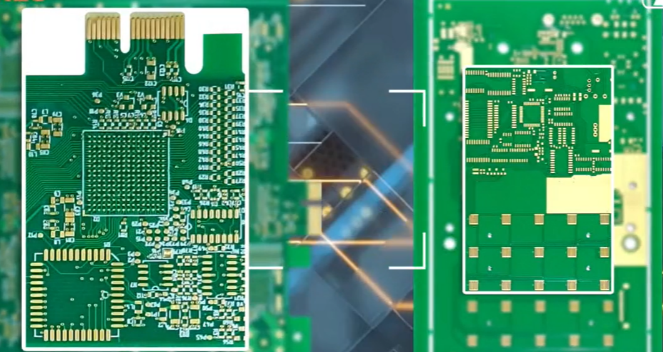

Babban Bambanci tsakanin PCB-Plated Gold and Immersion Gold PCB

Ƙirƙirar zinari mai nutsewa a cikin shimfidar yanayin da'irar da'irar daidaiton launi, haske mai kyau, shimfidar lebur, ingantaccen solderability na plating nickel-gold. Za a iya m zuwa kashi hudu matakai: pre-jiyya (degreasing, micro-etching, kunnawa, bayan dipping), nutsewa nickel, nutsewa zinariya, post-jiyya (sharar zinariya wanke, DI wanka, bushewa). Kaurin nutsar da zinari tsakanin 0.025-0.1um.

Zinariya da aka yi amfani da ita wajen maganin da'ira, saboda tsananin ƙarfin gwal, juriya mai kyau na iskar shaka, tsawon rai, aikace-aikace na gabaɗaya kamar faifan maɓalli, allon yatsa na zinari, da dai sauransu, da allunan da aka yi da zinari da zinariya- allunan nutsewa mafi mahimmancin bambanci shine cewa zinare-plated zinariya ne mai wuyar gaske, mafi juriya, yayin da zinare-zurfin zinari mai laushi ne mai ƙarancin lalacewa.