Dukkanmu mun san cewa a lokacin da ake samar da allunan da'ira na PCB, babu makawa a samu nakasu na lantarki kamar gajerun da'ira, buɗaɗɗen da'ira, da zubewa saboda abubuwan waje. Don haka, don tabbatar da ingancin samfur, allon kewayawa dole ne a yi gwaji mai tsauri kafin barin masana'anta.

Babban hanyoyin gwaji na PCB shine gwajin bincike na tashi da gwaji na gwaji.

1. Gwajin Binciken Flying

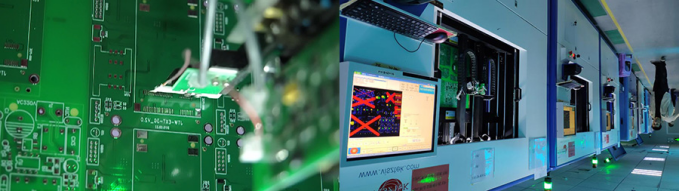

Gwajin bincike na tashi yana amfani da bincike 4 zuwa 8 don gudanar da gwaje-gwajen ci gaba mai ƙarfi da ƙarancin juriya akan allon da'ira, bincika buɗewa da gajerun kewayawa ba tare da buƙatar na'urorin gwaji na musamman ba. Wannan hanyar ta ƙunshi ɗaga PCB kai tsaye akan na'urar gwaji ta tashi sannan kuma gudanar da shirin gwajin don yin gwaje-gwaje. Amfanin gwajin gwajin jirgin sama shine cewa hanyar gwajinsa da aiki 流程 suna da matukar dacewa, adanawa akan farashin gwaji, kawar da lokacin da ake buƙata don samar da kayan aikin gwaji, da haɓaka haɓakar isarwa, yin shi. dace da samar da kananan batches na PCBs.

2.Gwajin Gyaran Gwaji

Kayan aikin gwaji ƙwararrun gwaji ne na gwaji da aka yi musamman don ci gaba da gwaji a samarwa. Kudin yin na'urorin gwaji yana da tsada sosai, amma suna ba da ingantaccen gwaji, kuma babu cajin sake yin oda, wanda kuma ke adana farashi ga abokin ciniki.

Hanyoyin gwaji guda biyu sun bambanta, haka ma injuna da kayan aikin da ake amfani da su. Ciki na kayan gwajin PCB an cika makil da wayoyi masu alaƙa da bincike. Idan aka kwatanta da gwajin binciken jirgin sama, da gaske yana shirya duk binciken da ya dace da wuraren da ake buƙatar gwadawa a kan allon kewayawa lokaci guda. Yayin gwaji, kawai danna saman sama da na ƙasa tare don gwada dukkan allo mai kyau ko mara kyau.