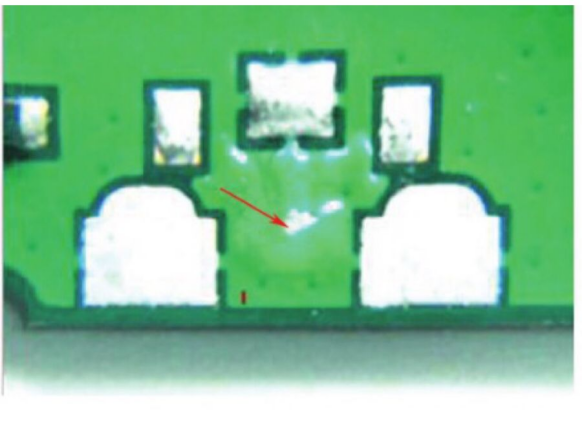

A cikin PCB solder tsayayya samar tsari, wani lokacin gamu da tawada kashe harka, dalilin za a iya m za a iya raba kashi uku masu zuwa wadannan maki.

1, PCB a cikin tawada bugu, pre-jiyya ba a wurin, kamar PCB Board surface tabo, kura ko ƙazanta, ko wani ɓangare na wurin da aka oxidized, a gaskiya, don warware wannan matsala ne sosai. sauki, sake yi da pre-jiyya sake a kan layi, amma dole ne mu yi jihãdi don tsaftace sama da kewaye hukumar surface stains, impurities, ko oxidized Layer.

2, baking circuit board short time ko zafin jiki bai isa ba, saboda da'ira a cikin bugu na heatset tawada bayan yin gasa a yanayin zafi mai zafi, kuma idan zafin yin burodi ko lokacin bai isa ba zai haifar da ƙarfin. da tawada a saman allon.

3, matsalolin ingancin tawada ko ranar ƙarewar tawada, ko siyan sanannun samfuran tawada, wannan kuma zai haifar da tawada na allo a kan murhu idan an jefar.