A yau, za mu ci gaba da bincika hanyoyi uku na kera ginshiƙan PCB SMT: Chemical Etching (Chemical Etching Stencil), Laser Cutting (Laser Cutting Stencil), da Electroforming (Electroformed Stencil).

Bari mu fara samar da sinadarin etching:

1.

2. Tsari Tafiya: Yanke takardar bakin karfe zuwa girman da ya dace → Tsaftace → Aiwatar da kayan aikin hoto → {94} → Ci gaba kuma bushe → Sinadaran etching → {18} St. kayan photoresist → Tsaftace kuma bushe → Duba {49091024} {096} Tashin hankali → Kunshin.

3. Fasaloli: Ƙirƙirar lokaci ɗaya, da sauri gudun; maras tsada.

4. Rashin hasara: Ragewa ga ƙirƙirar sa'o'i (glasss) rashin isassun etching) ko haɓaka girman buɗe ido (over-etching); tasiri sosai ta hanyar dalilai masu haƙiƙa (kwarewa, sinadarai, fim), matakan samarwa da yawa, manyan kurakurai masu tarin yawa, waɗanda ba su dace da samar da stencil mai kyau ba; tsarin samar da gurɓatacce ne kuma bai dace da muhalli ba, kuma a hankali ya ƙare.

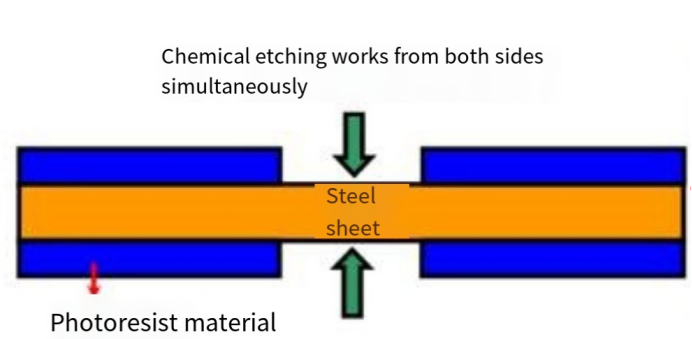

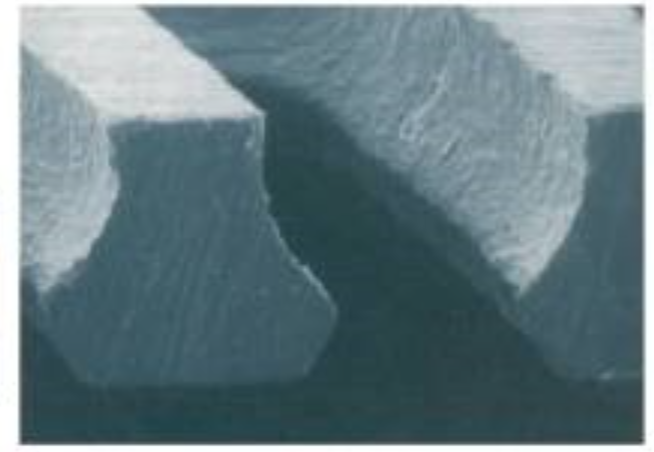

Tunda etching sinadaran ke aiki daga ɓangarorin biyu na takardar ƙarfe don cire sassan ƙarfe (kamar yadda aka nuna a hoton hagu na ƙasa), bangon ramin suna santsi kuma a tsaye. Duk da haka, maiyuwa ba zai cire gaba daya karfen da ke tsakiyar kaurin takardar ba, yana yin siffa mai kamanni, kuma sashin giciye ya bayyana a cikin sifar mazurari (kamar yadda aka nuna a hoto na sama). Wannan tsarin bai dace ba don sakin manna solder. Sabili da haka, ba a ba da shawarar ƙwanƙwasa ƙwanƙwasa gabaɗaya don daidaitattun abubuwan haɗin ginin ba. Abubuwan da ke da farar fil ƙasa da 0.5mm ko ƙasa da girman 0402 ba a ba su shawarar yin amfani da fensir mai ƙyalƙyali ba. Tabbas, don haɗuwa da wasu manyan abubuwan haɗin gwiwa ko abubuwan haɗin gwiwa tare da ƙimar farar girma, ƙirar ƙira suna da fa'idar tsada mai mahimmanci kuma suna iya biyan buƙatun ingancin samarwa na abokan ciniki da yawa da masana'antar sarrafa wuri-da-wuri na SMT.

A cikin labarin na gaba, za mu gabatar da hanyar yankan Laser a cikin PCB SMT stencil.