Ƙayyadaddun tsari na masana'anta na SMT ya ƙunshi abubuwa masu mahimmanci da yawa da matakai don tabbatar da inganci da daidaito na stencil. Yanzu bari ' s koyi game da {49049101} } mahimman abubuwan da ke ciki samar da SMT stencils:

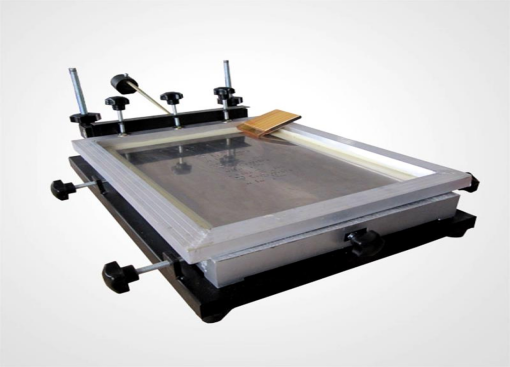

1. Frame: Firam na iya zama ko dai cirewa ko gyarawa. Firam masu cirewa suna ba da izinin sake amfani da firam ta hanyar canza takardan stencil, yayin da ƙayyadaddun firam ɗin suna amfani da m don haɗa raga zuwa firam. Girman firam ɗin an ƙaddara ta buƙatun na'urar firintar manna, tare da masu girma dabam kamar 29" x 29" (736 x 736 mm) don injuna kamar ƙirar DEK 265 da MPM UP3000. Firam abu yawanci aluminum gami, tare da kauri na 40 ± 3mm da flatness haƙuri na ba fiye da 1.5mm.

2. Rago: Ana amfani da raga don tabbatar da fensir da firam kuma ana iya yin ta da bakin karfe waya ko babban polyester polymer. Ana amfani da ragar bakin ƙarfe na waya tare da adadin raga kusan 100, yana ba da kwanciyar hankali da isasshen tashin hankali. Hakanan ana amfani da ragar polyester don ƙarfinsa da juriya ga nakasu.

3. Stencil Sheet: Tambarin stencil, ko foil, an yi shi ne daga abubuwa kamar bakin karfe, tare da kauri daga 0.08mm zuwa 0.3mm (4-12 MIL). Zaɓin kayan abu da kauri yana da mahimmanci don dorewar stencil, juriya na lalata, ductility, da haɓakar haɓakar thermal, wanda ke shafar rayuwar sabis na stencil kai tsaye.

4. Adhesive: Adhesive: Adhesive da ake amfani da shi don haɗa firam da tambarin stencil yana taka muhimmiyar rawa a aikin stencil. Dole ne ya kula da haɗin gwiwa mai ƙarfi kuma ya yi tsayayya da nau'ikan tsaftacewa daban-daban ba tare da amsa sinadarai ba.

5. Tsari Tsari: Tsarin stencil na iya haɗawa da dabaru daban-daban kamar yankan Laser, etching chemical, ko electroforming. Yanke Laser hanya ce ta gama gari wacce ke amfani da lasers masu ƙarfi don yin daidai-yanke takardar stencil, sannan ta hanyar lantarki don rage ƙarancin bangon ramin. Wannan hanyar ta dace da na'urori masu kyau kuma suna ba da babban matakin daidaito da tsabta .

6. Tsarin Stencil: Zane-zane na stencil ya haɗa da girman buɗewa, wanda ke da mahimmanci don sarrafa ingancin aikin bugu na solder. Girman buɗaɗɗen ya kasance ɗan ƙarami kaɗan fiye da girman kushin akan PCB, musamman don na'urori masu kyau, don hana al'amura kamar ƙwallayen siyar ko gadoji.

7. Tashin hankali na Stencil: Damuwa na stencil yana da mahimmanci don aikinsa kuma yawanci ana auna shi a maki tara akan takardar stencil. Ya kamata tashin hankali ya kasance cikin kewayon ƙayyadaddun kewayon, kamar girma ko daidai da 40N/cm don sabon zanen stencil, kuma a maye gurbinsa idan ya faɗi ƙasa da 32N/cm.

8. Alamar Alama: Alamar maki akan stencil suna da mahimmanci don daidaitaccen daidaitawa tare da PCB yayin aikin bugu. Ya kamata lamba da matsayi na waɗannan maki su yi daidai da maki a kan PCB .

9. Zaɓin Kauri na Stencil: An zaɓi kauri na takardar stencil bisa mafi ƙarancin farar kushin da girman bangaren akan PCB. Ana amfani da stencil na bakin ciki don mafi kyawun filaye, yayin da ake amfani da stencil masu kauri don manyan filaye.

A taƙaice, ana iya tattara ƙa'idodin amfani da stencil a cikin waɗannan abubuwan:

1. Apertures trapezoidal ne ta dabi'a, tare da budewar sama yawanci kasancewa 1 zuwa 5mil mafi girma fiye da na ƙasa, wanda ke sauƙaƙe fitar da manna solder.

2. Jurewar girman buɗaɗɗiyar kusan 0.3 zuwa 0.5mil, tare da daidaiton matsayi na ƙasa da 0.12mil.

3. Kudin ya fi etching sinadarai amma ƙasa da stencil na lantarki.

4. Ganuwar ramin ba su da santsi kamar na samfuran lantarki.

5. Mafi girman kauri don ƙirƙira samfuri shine 0.12 zuwa 0.3mm.

6. Ana ba da shawarar gabaɗaya don bugawa tare da ƙimar farar abubuwa na mil 20 ko ƙasa da haka.

Ta hanyar bin waɗannan ƙayyadaddun bayanai da matakai, Sanxis na iya tabbatar da cewa stencils na S. kuma abin dogara solder manna bugu.

A cikin labarin labarai na gaba, za mu gabatar da abubuwan da ake buƙata don ƙirƙira na SMT stencil.