Wireless PCB madannai na caca (allon da'irar da aka buga) babban sashi ne da aka ƙera don maɓallan caca mara waya, da nufin samar da ingantaccen haɗin kai mara igiyar waya da ingantaccen ƙwarewar mai amfani.

PCB Don Allon madannai na Wasan Mara waya Gabatarwar samfur

|

|

1. Bayanin Samfura

PCB allon madannai na caca mara waya (allon da'irar da aka buga) babban sashi ne da aka ƙera don maɓallan caca mara waya, da nufin samar da ingantaccen haɗin kai mara igiyar waya da ingantaccen ƙwarewar mai amfani. Ana amfani da su sosai a fannoni da yawa kamar wasanni, ofis da nishaɗi.

2. Abubuwan Samfura

Fasahar sadarwar mara waya

Goyi bayan ka'idojin sadarwa mara waya kamar Bluetooth da 2.4GHz don tabbatar da ƙarancin latency da kwanciyar hankali.

Samun ikon hana tsangwama mai ƙarfi don tabbatar da amfani na yau da kullun a cikin hadaddun mahalli.

Ƙirar da'ira mai girma

Ɗauki kayan aikin lantarki masu inganci don tabbatar da daidaito da amincin watsa sigina.

Ƙirar ƙarancin wutar lantarki don tsawaita rayuwar baturi kuma ya dace da wasan kwaikwayo na dogon lokaci.

Haɗin ayyuka da yawa

Haɗa ayyuka da yawa kamar hasken baya na RGB, shirye-shiryen macro, sarrafa ƙara, da sauransu don haɓaka ƙwarewar mai amfani.

Taimakawa aikin musanya mai zafi don sauƙaƙe masu amfani don maye gurbin maɓallan maɓalli da masu sauyawa.

Karamin shimfidar wuri

Ƙirƙiri ƙaƙƙarfan ƙira na PCB don adana sarari da dacewa da maɓallan madannai masu girma dabam dabam.

Ƙirƙirar ƙira don rage tsangwama da haɓaka aikin gabaɗaya.

3. Bayanan Fasaha

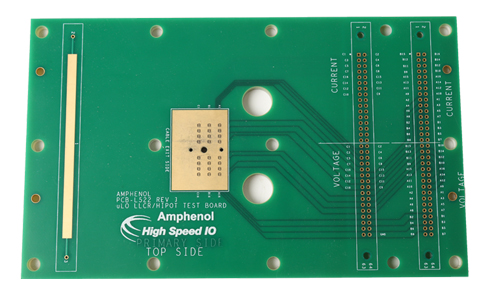

| Adadin yadudduka | 2 yadudduka | Launin tawada | koren man mai tare da farar haruffa |

| Abu | FR-4 S1141 | Mafi qarancin nisa/tsawon layi | 0.1mm/0.1mm |

| Kauri | 3.0mm | Abubuwan fasali | sarrafa zurfin nutsewa 2.0MM |

| Kaurin jan karfe | 1oz Layer na ciki, 1oz na waje Layer | Maganin saman | gwal na nutsewa |

4. Yankunan Aikace-aikace

Allon madannai na caca

An tsara shi don yan wasa, yana ba da amsa cikin sauri da ƙwarewar bugawa mai daɗi.

Allon madannai na ofishi

Ya dace da amfani na dogon lokaci, rage gajiya da inganta aikin aiki.

Ikon multimedia

Ana iya amfani dashi don masu sarrafa multimedia don sauƙaƙe masu amfani don daidaita ƙarar da sarrafa sake kunnawa.

Tsarin sarrafawa

Zaɓin kayan aiki

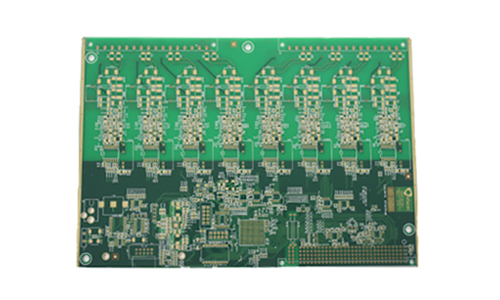

Kayayyakin gama gari sun haɗa da FR-4 da kayan mitoci masu girma don tabbatar da aiki da dorewa na hukumar kewayawa.

Tsarin bugawa

Karɓar bugu na allo na gaba da fasahar hoto don tabbatar da daidaiton layin.

Tsarin taro

Karɓar fasahar ɗorawa ta saman (SMT) don tabbatar da ƙarfi da amincin abubuwan haɗin gwiwa.

5.Kwayoyin inganci

Tsananin gwaji

Ciki har da gwajin aiki, gwajin siginar mara waya, jurewar gwajin wuta, da sauransu, don tabbatar da ingancin kowane PCB.

Yarda da ƙa'idodin duniya

An wuce ISO9001 da sauran takaddun takaddun tsarin gudanarwa don tabbatar da cewa samfurin ya cika ƙa'idodin ƙasa da ƙasa.

|

|

{71666654} 6.Kammala

Maɓallin madannai na caca mara waya ta PCB allon kewayawa shine ainihin abin da ke cikin madannai na caca mara waya ta zamani. Tare da babban aikinsa da ƙira mai yawa, yana ba masu amfani da ƙwarewar amfani mai kyau. Zaɓin masana'anta da kayan da suka dace na iya tabbatar da kwanciyar hankali da amincin madannai na caca mara waya da biyan bukatun masu amfani daban-daban.

FAQ

Tambaya: Ma'aikata nawa kuke da su a masana'antar ku?

A: Fiye da 500.

Tambaya: Shin kayan da kuke amfani da su sun dace da muhalli?

A: Abubuwan da muke amfani da su sun yi daidai da ma'aunin ROHS da ma'aunin IPC-4101.

Tambaya: Waɗanne matsaloli ne za a iya haifar da rashin daidaitattun ƙirar PCB a cikin wayoyin hannu?

A: Idan ƙirar da'irar ba ta da madaidaicin tsari, yana iya haifar da tsangwama na sigina da rashin kwanciyar hankali, ta haka yana shafar aikin gabaɗayan wayar. Saboda haka, muna buƙatar cikakken la'akari da matsayi na kowane bangare da kuma ma'anar wayoyi a lokacin ƙirar PCB.

Tambaya: Shin rashin kulawa sosai yayin aikin samarwa zai iya haifar da matsaloli da yawa?

A: A cikin tsarin samarwa, al'amurran da suka shafi kamar kauri mara daidaituwa da milling mara kyau na iya yin tasiri ga aikin PCB. Sabili da haka, tsananin kulawa da tsarin samarwa shine mabuɗin don tabbatar da inganci.