6 -Layer 3-mataki HDI PCB ana amfani dashi sosai a cikin sadarwa, kwamfutoci, na'urorin lantarki da sauran fagage.

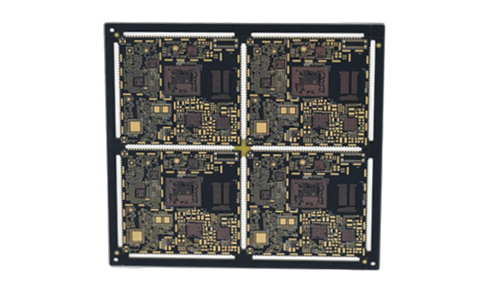

16-Layer 3-Level HDI PCB Samfurin Gabatarwar

1. Bayanin Samfura

6-Layer 3-mataki HDI PCB ana amfani dashi sosai a cikin sadarwa, kwamfutoci, na'urorin lantarki da sauran fagage. An tsara shi don biyan buƙatun na'urorin lantarki na zamani don saurin gudu, mita mai yawa da yawa.

2. Abubuwan Samfura

1.High Layer ƙididdiga ƙididdiga:

Tsarin Layer 2.16, wanda zai iya tallafawa ƙira mai sarƙaƙƙiya da haɗakar ayyuka da yawa.

Fasahar 3.HDI:

4.Kwantar da fasahar haɗin kai mai girma, zai iya cimma ƙaramin tazara da mafi girman layin layi.

Taimakawa micro makafi rami da fasahar rami binne, inganta amincin watsa sigina.

5.Mafi girman aikin lantarki:

6.Ƙarancin juriya da ƙananan halayen inductance, dace da watsa sigina mai sauri.

Ingantaccen tsarin tarawa, rage tsangwama da sigina.

7.Kyakkyawan aikin kawar da zafi:

8.Kwantar da manyan abubuwan da ke haifar da zafi don tabbatar da zubar da zafi a ƙarƙashin babban aiki mai nauyi.

9. Zaɓuɓɓukan abu da yawa:

10. Za'a iya samar da ma'auni daban-daban bisa ga bukatun abokin ciniki, kamar FR-4, Rogers, da dai sauransu.

3. Yankunan Aikace-aikace

Kayan aikin sadarwa: irin su tashoshi, na'urori masu amfani da wutar lantarki, masu sauyawa, da sauransu.

Kayan lantarki na mabukaci: irin su smart phones, tablets, game consoles, etc.

Kayan aikin masana'antu: kamar tsarin sarrafa sarrafa kansa, kayan aikin likita, da sauransu.

Kayan lantarki na kera motoci: kamar tsarin nishaɗin cikin mota, tsarin kewayawa, da sauransu.

4.Technical Parameters

| Sunan samfur | 16-Layer 3-mataki HDI PCB | Faɗin layi da tazara | 4MIL/4MIL |

| Amfani da samfur | module | Ta | 0.2MM |

| Kaurin allo | 2.0MM | Ikon matsawa | +/-8% |

| Launi | koren mai da farin haruffa | Tsarin jiyya na saman | gwal na nutsewa 2U |

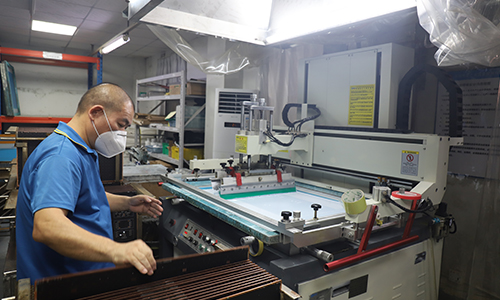

5.Tsarin samarwa

Daidaitaccen etching: tabbatar da inganci da daidaiton layin.

Lamination Multi-Lamination: cimma kwanciyar hankali na allunan Layer Layer ta hanyar zafin jiki da matakan matsa lamba.

Maganin saman: samar da hanyoyi daban-daban na maganin saman, kamar HASL, ENIG, da sauransu don biyan buƙatu daban-daban.

|

|

6.Kwayoyin inganci

Ƙuntataccen ƙa'idodin gwaji: gami da gwajin aikin lantarki, gwajin yanayin zafi, gwajin ƙarfin injina, da sauransu.

Takaddun shaida na ISO: saduwa da ƙa'idodin duniya don tabbatar da ingancin samfur da amincin.

7.Taƙaice

16-Layer 3-level HDI wani muhimmin sashi ne mai mahimmanci a cikin samfuran lantarki na zamani. Tare da babban aikin sa, babban yawa da halayen lantarki mafi girma, yana biyan bukatun aikace-aikace masu girma daban-daban. Mun himmatu don samar wa abokan ciniki da ingantaccen ingancin HDI PCB mafita don taimakawa abokan ciniki samun fa'ida a cikin gasa mai zafi na kasuwa.

FAQ

1.Q: Yaya nisa masana'antar ku daga filin jirgin sama mafi kusa?

A: Kimanin kilomita 30

2.Q: Menene mafi ƙarancin odar ku?

A: Guda ɗaya ya isa yin oda.

3.Q: Yaushe zan iya samun tsokaci bayan na samar da Gerber, bukatun tsarin samfur?

A: Ma'aikatan tallace-tallacen mu za su ba ku magana a cikin awa 1.

4.Q. Wadanne matsaloli ne gama gari ga hukumar da'ira ta PCB ta haɗin kai ta HDI ta sabani?

A: Akwai tambayoyi masu zuwa:

1) Lalacewar walda: Lalacewar walda ɗaya ne daga cikin matsalolin da aka fi sani a masana'antar da'ira ta HDI kuma tana iya haɗawa da walda mai sanyi, gadar walda, da fasa walda. Maganganun waɗannan matsalolin sun haɗa da haɓaka sigogin siyarwar, ta amfani da ingantaccen solder da juyi, da kiyaye kayan walda akai-akai.

2) Matsalolin Sake aiki: Sake yin aiki wani tsari ne da babu makawa a masana'antar da'ira ta HDI, musamman idan aka sami lahani. Hanyoyin sake yin aiki da kyau na iya tabbatar da aiki da amincin hukumar. Hanyoyin magance matsalolin sake aiki sun haɗa da yin amfani da kayan aikin da suka dace, daidaitaccen wuri mai lahani, da kula da zafin jiki da lokaci.

3) Ganuwar Ramin Ramin: A cikin tsarin masana'antar HDI, hako ramukan da bai dace ba na iya haifar da bangon rami mara kyau, yana shafar aikin allo. Maganganun sun haɗa da yin amfani da madaidaicin rawar soja da tabbatar da cewa saurin hakowa yana da matsakaici, da kuma inganta sigogin hakowa don haɓaka ingancin bangon rami.

4) Matsaloli masu inganci: plating wani muhimmin sashi ne na tsarin kera hukumar HDI, platin da bai dace ba zai haifar da kauri marar daidaituwa, yana shafar aikin hukumar. Magani sun haɗa da jiyya na ƙasa don cire oxides da ƙazanta, da haɓaka sigogin plating don inganta ingancin plating.

5)Matsalar baka: Saboda yawan yadudduka a allunan HDI, akwai yuwuwar samun matsalolin wargin yayin aikin kera. Magani sun haɗa da sarrafa zafin jiki da zafi, da haɓaka ƙira don rage haɗarin faɗakarwa.

6)Gajeren kewayawa da na'urori masu rarrabawa: Wannan yana ɗaya daga cikin manyan laifuffuka. Gajerun da'ira shine haɗin da ba a yi niyya ba tsakanin madugu biyu ko fiye a cikin da'ira wanda bai kamata a haɗa shi ba; na'ura mai karyawa wani bangare ne na da'ira da aka yanke, wanda ke haifar da gazawar gudanawar yanzu. Gajerun kewayawa haɗin haɗari ne tsakanin madugu biyu ko fiye a cikin da'ira da yakamata a haɗa su.

7)Lalacewar bangare: lalacewar bangaren kuma daya ne daga cikin nau'ikan gazawar da aka saba yi, na iya zama saboda wuce gona da iri, tsananin zafi, rashin karfin wutar lantarki da wasu dalilai.

8) PCB Layer peeling: PCB Layer peeling yana nufin allon da'irar da ke cikin Layer da Layer tsakanin abin da ke faruwa na rabuwa. Irin wannan gazawar yawanci ana haifar da ita ne ta hanyar walda mara kyau ko zafin zafi.