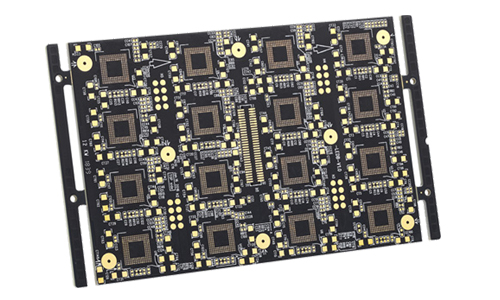

12 -Layer high-density arbitrary interconnection circuit board (HDI PCB) fasaha ce ta ci gaba da ake amfani da ita a cikin kayayyakin lantarki, musamman a wayoyin hannu, allunan, na'urorin likitanci da na'urorin lantarki na mota.

Babban Haɗin Haɗin PCB Gabatarwar Samfur

1. Bayanin Samfura

12-Layer high-density arbitrary interconnection board (HDI PCB) fasaha ce ta ci-gaba da ake amfani da ita a cikin kayayyakin lantarki, musamman a wayoyin hannu, kwamfutar hannu, na'urorin likitanci da na'urorin lantarki na mota. Samfurin yana samun ƙaramin girma, mafi girman aiki da ingantaccen siginar sigina ta hanyar ƙira mai yawa da fasahar haɗin kai mai girma.

2. Abubuwan Samfura

1. Babban ƙira

Tsarin Layer Multi-Layer: Tsarin Layer 12 na iya haɗa ƙarin da'irori a cikin iyakataccen sarari.

Karamin buɗe ido: Amfani da fasahar buɗaɗɗen buɗaɗɗiya tana goyan bayan mafi girman yawan wayoyi.

2. Mafi girman aikin lantarki

Ƙananan asarar sigina: Ingantaccen tsarin tarawa da zaɓin kayan aiki don rage asarar a watsa sigina.

Kyakkyawan ikon hana tsangwama: Inganta ƙarfin tsoma baki ta hanyar ƙirar ƙasa mai ma'ana da shimfidar madaurin wuta.

3. Ingantacciyar kula da thermal

Ayyukan watsawa na zafi: Yin amfani da kayan aiki na thermal da zane yana tabbatar da kwanciyar hankali da amincin kayan aiki a ƙarƙashin babban kaya.

4. Zaɓuɓɓukan ƙira masu sassauƙa

Haɗin kai tsaye: Yana goyan bayan ƙira mai rikitarwa don biyan buƙatun samfura daban-daban.

Zaɓuɓɓukan abu da yawa: Za'a iya zaɓin sassa daban-daban bisa ga bukatun abokin ciniki, kamar FR-4, polyimide, da sauransu.

3.Ma'auni na Fasaha

| Adadin yadudduka | 12 | Solder mask | rubutu na baki da fari |

| Abu | TU768 | Mafi ƙarancin buɗe ido | Laser rami 0.1mm, inji rami 0.15mm |

| Rabon Halaye | 6:1 | Layi nisa/Tazarar layi | 2mil/2mil |

| Kauri | 1.0mm | Abubuwan fasaha | 4+N+4 |

| Maganin saman | gwal na nutsewa | / | / |

4. Yankunan Aikace-aikace

Kayan lantarki na mabukaci: wayoyi masu wayo, kwamfutar hannu, na'urori masu sawa, da sauransu.

Kayan aikin masana'antu: tsarin sarrafawa ta atomatik, na'urori masu auna firikwensin, da sauransu.

Kayan aikin likita: kayan aikin sa ido, kayan bincike, da sauransu.

Kayan lantarki na kera motoci: tsarin nishaɗin cikin mota, tsarin kewayawa, da sauransu.

5.Tsarin samarwa

Ƙirƙirar ƙira mai ƙima: ta yin amfani da kayan aikin masana'antu na ci gaba da matakai don tabbatar da daidaito da amincin samfurori.

Ƙaƙƙarfan kulawar inganci: kowane hanyar haɗin samarwa yana fuskantar ingantaccen bincike don tabbatar da cewa samfuran sun cika ƙa'idodin ƙasashen duniya.

|

|

{71666654} 6.Kammala

The 12-Layer high-density high density interconnection board is a high-performance, high-mofiability board circuit solution that can meet the modern electronic products for miniaturization, high work and high density. Mun himmatu wajen samar wa abokan ciniki samfurori da ayyuka masu inganci, taimaka wa abokan ciniki su yi nasara a gasar kasuwa mai zafi.

FAQ

Tambaya: Yaya nisan masana'antar ku daga filin jirgin sama?

A: 30 km.

Tambaya: Menene MOQ ɗin ku?

A: 1 PCS.

Tambaya: Bayan samar da Gerber, bukatun aiwatar da samfur, yaushe zan iya samun ƙima?

A: Maganar PCB cikin awa 1.

Q:HDI matsananciyar haɗin kai ta PCB matsalolin gama gari kamar haka:

4.1 Lalacewar siyarwa: Lalacewar siyarwa ɗaya ne daga cikin mafi yawan matsalolin da ake samu a masana'antar keɓancewar da'ira ta HDI, waɗanda za su iya haɗawa da walda mai sanyi, gadar solder, fasar solder, da dai sauransu. Maganin waɗannan matsalolin sun haɗa da inganta sigogin siyarwar, ta amfani da manyan sigogi. - quality solder da juyi, da kuma a kai a kai rike soldering kayan aiki.

4.2 Matsalolin Sake aiki: Sake yin aiki wani tsari ne da babu makawa a masana'antar da'ira ta HDI, musamman idan aka sami lahani. Daidaitaccen fasahar sake yin aiki zai iya tabbatar da aiki da amincin allon kewayawa. Hanyoyin warware matsalolin sake aiki sun haɗa da yin amfani da kayan aikin da suka dace, daidaitaccen matsayi na lahani, da sarrafa zafin sake aiki da lokaci1.

4.3 Bangon rami mai kauri: Yayin aikin kera allunan HDI, hakowa mara kyau na iya haifar da bangon rami mara kyau, yana shafar aikin allon kewayawa. Magani sun haɗa da yin amfani da madaidaicin rawar soja, tabbatar da saurin hakowa matsakaiciya, da haɓaka sigogin hakowa don haɓaka ingancin bangon rami.

4.4 Lamurra masu inganci: Plating shine maɓalli mai mahimmanci a cikin tsarin kera allon HDI. Platin da ba daidai ba na iya haifar da kauri mara daidaituwa, yana shafar aikin allon kewayawa. Magani sun haɗa da jiyya na ƙasa don cire oxides da ƙazanta, da haɓaka sigogin plating don inganta ingancin plating2.

4.5 Matsalolin warping: Saboda yawan yadudduka na allon HDI, matsalolin rikice-rikice suna da yuwuwar faruwa yayin aikin masana'anta. Magani sun haɗa da sarrafa zafin jiki da zafi, da haɓaka ƙira don rage haɗarin warping.

4.6 Gajeren kewayawa da buɗaɗɗen kewayawa: Wannan yana ɗaya daga cikin nau'ikan laifuffuka da aka fi sani. Ƙaƙwalwar kewayawa tana nufin haɗin haɗari tsakanin masu gudanarwa biyu ko fiye a cikin da'ira wanda bai kamata a haɗa shi ba; buɗaɗɗen kewayawa yana nufin wani ɓangaren da'irar da aka yanke, wanda ke haifar da gazawar na yanzu.

4.7 Lalacewar sassa: Lalacewar sassa kuma nau'in gazawa ce ta yau da kullun, wanda ƙila ya faru ta hanyar wuce gona da iri, zafi mai zafi, rashin kwanciyar hankali, da sauransu.

4.8 PCB peeling Layer: PCB peeling peeling yana nufin rabuwa tsakanin yadudduka a cikin allon kewayawa. Yawanci ana haifar da wannan gazawar ne ta hanyar walda mara kyau ko kuma yawan zafin jiki.