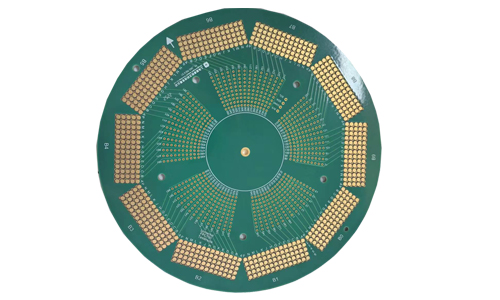

20-Layer IC masana'antu kula da gwajin substrate ne a high-yi PCB tsara don hadedde kewaye (IC) gwaji da kuma masana'antu sarrafa aikace-aikace.

20-Layer IC Industrial Control Test Substrate Gabatarwar samfur {2492086}

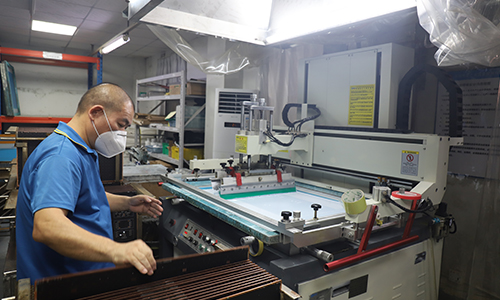

1. Bayanin Samfura 20-Layer IC masana'antu kula da gwajin substrate wani babban aiki PCB tsara don hadedde kewaye (IC) gwajin da masana'antu sarrafa aikace-aikace. Substrate yana ɗaukar tsari mai yawa da kayan haɓaka don samar da ingantaccen siginar siginar, sarrafa zafi da aminci. Ana amfani da shi sosai a cikin kayan aiki na atomatik, tsarin sarrafa masana'antu, tsarin da aka haɗa da kayan gwaji. 2. Abubuwan Samfura 1. Ƙirar haɗin kai mai girma: Tsarin Layer 2.20 yana goyan bayan manyan wayoyi masu yawa, yana dacewa da buƙatun ƙira mai rikitarwa, kuma yana tabbatar da inganci da kwanciyar hankali na watsa sigina. 3.Kyakkyawan aikin lantarki: 4.Yi amfani da ƙananan dielectric akai-akai (Dk) da ƙananan asarar dielectric (Df) kayan don inganta watsa sigina, rage jinkirin sigina da tunani, da inganta aikin gabaɗaya. 5.Kyakkyawan kula da zubar da zafi: 6. Ana yin la'akari da maganin zubar da zafi a cikin zane. Ta hanyar ingantaccen fasahar sarrafa zafin jiki, ana tabbatar da kwanciyar hankali na thermal a ƙarƙashin yanayin aiki mai nauyi don tsawaita rayuwar sabis na substrate. 7. Babban Aminci: 8. Bayan tsananin kula da ingancin muhalli da gwajin muhalli, an tabbatar da amincin samfurin a ƙarƙashin yanayi daban-daban masu tsauri, wanda ya dace da aikace-aikacen masana'antu tare da aiki na dogon lokaci. 9. Aikin gwaji mai ƙarfi: 10.Multiple gwajin musaya da kuma aiki modules an hadedde a cikin substrate zane don tallafawa sauri da kuma daidai gwajin IC don saduwa da bukatun daban-daban aikace-aikace. 11. Matsala mai sassauƙa: 12. Samar da hanyoyin sadarwa da yawa da zaɓuɓɓukan haɗi, kamar USB, UART, SPI, I2C, da sauransu, don sauƙaƙe haɗin kai tare da wasu na'urori da kayayyaki. 3. Bayanan Fasaha 4. Yankunan Aikace-aikace Kayan aiki na masana'antu: Ana amfani da shi don gwaji da tabbatar da tsarin sarrafawa da kayan aiki na atomatik. Tsarukan da aka haɗa: goyan bayan haɓakawa da gwaji na aikace-aikacen da aka haɗa daban-daban. Kayan aikin gwaji na lantarki: azaman dandalin gwaji, ana amfani da shi don kimanta aiki da warware matsalar haɗaɗɗun da'irori. Na'urorin IoT: suna goyan bayan haɓakawa da gwajin samfuran masu alaƙa da IoT. 5.Tsarin samarwa Daidaitaccen etching da hakowa na Laser: tabbatar da daidaiton zane-zanen da'ira don biyan buƙatun ƙira na haɗin haɗin kai mai girma (HDI). Fasahar lamination Multi-Lamination Technology: Yi amfani da babban zafin jiki da tsarin matsa lamba don haɗa nau'i daban-daban na kayan don tabbatar da aikin lantarki da ƙarfin inji. Maganin saman: ana iya zaɓar hanyoyin magance nau'ikan nau'ikan jiyya, kamar sinadarai na zinare (ENIG), matakin iska mai zafi (HASL), da sauransu, don haɓaka amincin walda da juriya na lalata. {71666654} 6.Kammala 20-Layer IC masana'antu kula da gwajin substrate ya zama wani makawa kayan aiki a cikin zamani masana'antu iko da hadedde da'ira gwajin tare da kyakkyawan yi, amintacce da sassauƙan aikace-aikace halaye. Ko cikin sharuddan siginar siginar, sarrafa zafin jiki ko ayyukan gwaji, ƙirar ta nuna fa'idodi masu mahimmanci, yana taimakawa haɓakawa da tabbatar da samfuran lantarki daban-daban. FA Q Tambaya: Menene ya kamata mu yi la'akari da lokacin zayyana irin wannan PCB? A: Kamar haka, 1. Tabbatar cewa duk abubuwan ƙira sun bi ka'idodin IPC: Yi amfani da kayan aikin Ka'idodin Tsare-tsare na atomatik (DRC) don ganowa da gyara batutuwa. 2. Zaɓi abin da ya dace daidai da buƙatun aikace-aikacen: Yi la'akari da amfani da manyan kayan Tg don inganta dogaro. 3. Ƙarfin aiki: Sadarwa tare da tsari don fahimtar iyawar masana'antu da iyakoki, guje wa ƙira masu rikitarwa. 4. Yi amfani da dabarun daidaita matsi: Sarrafa faɗin alamar alama da tazarar tsaka-tsakin don rage sigina da tunani. 5. Zana daidaitattun wutar lantarki da shimfidu na jirgin ƙasa: Yi amfani da na'urori masu haɗawa da tacewa don daidaita wutar lantarki. 6. Yi amfani da kayan aikin kwaikwayo na thermal: Yi tsinkaya da haɓaka aikin zafi, zaɓi kayan sarrafa zafi masu dacewa da ƙira. 7. Bi ka'idodin ƙirar EMI: Gudanar da gwajin EMI da takaddun shaida. 8. Gudanar da gwaje-gwajen dogaro: Irin su gwajin zafin jiki da zafi, gwajin keken zafi, yin amfani da ƙira marar amfani da hanyoyin gano kuskure. 9. Gudanar da cikakken gwaji da tabbatarwa yayin lokacin ƙira: Yi amfani da kayan gwaji na atomatik da software don haɓaka ƙwarewar gwaji da daidaito. 10. Yi la'akari da abubuwan farashi a farkon ƙirar ƙira: Inganta ƙira don rage yawan amfani da kayan aiki da ƙira.

Adadin yadudduka

20 yadudduka

Launin tawada

koren mai farin rubutu

Abu

FR-4, SY1000-2

Mafi qarancin nisa/tsawon layi

0.1mm/0.1mm

Kauri

5.0mm

Akwai abin rufe fuska na solder

ba

Kaurin jan karfe

Layer na waje 0.1 na ciki 1OZ

Maganin saman

gwal na nutsewa