Bari ’ s ci gaba da koyan tsari game da ƙirƙira ƙumburi.

1. Wafer mai shigowa da tsafta:

Kafin fara aikin, shimfidar wafer na iya samun gurɓataccen ƙwayar cuta, barbashi, yadudduka oxide, da sauransu, waɗanda ke buƙatar tsaftacewa, ko dai ta hanyar bushewa ko bushewa hanyoyin tsaftacewa.

2. PI-1 Litho: (Layer na Farko Photolithography: Polyimide Coating Photolithography)

Polyimide (PI) abu ne mai rufewa wanda ke aiki azaman rufi da tallafi. Da farko an rufe shi a kan wafer surface, sa'an nan kuma fallasa, tasowa, kuma a karshe an halicci wurin budewa ga bump.

3. Ti / Cu Sputtering (UBM):

{34836444440} UBM yana tsaye don a ƙarƙashin ƙarfe na baya, wanda galibi don dalilai masu zuwa. Ana yin UBM yawanci ta amfani da sputtering magnetron, tare da nau'in iri na Ti/C shine ya fi kowa.

4. PR-1 Litho (Hoton hoto na biyu: Photoresist Photolithography):

Photolithography na photoresist zai ƙayyade siffar da girman ƙumburi, kuma wannan mataki yana buɗe wurin da za a yi amfani da shi.

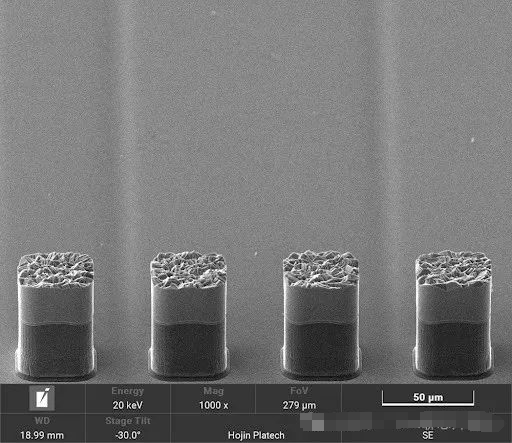

5. Sn-Ag Plating:

Yin amfani da fasaha na lantarki, tin-azurfa alloy (Sn-Ag) ana ajiye shi a wurin buɗewa don haifar da bumps. A wannan lokacin, ƙullun ba su da siffar zobe kuma ba a sake yin kwarara ba, kamar yadda aka nuna a hoton murfin.

6. Tashar PR:

Bayan an gama aikin lantarki, ana cire sauran photoresist (PR), yana fallasa abin da aka rufe a baya.

7. UBM Etching:

Cire Layer karfen UBM (Ti/Cu) sai dai a wurin da ake cin karo da juna, a bar karfen kawai a karkashin tururuwa.

8. Maimaitawa:

Wuce ta hanyar reflow soldering don narkar da gwangwani-azurfa gami da bar shi ya sake gudana, yana samar da siffa mai santsi.

9. Wurin Wuta:

Bayan an gama reflowing soldering kuma an samu bumps, ana aiwatar da guntu jeri.

Tare da wannan, aikin juye guntu ya cika.

A sabon na gaba, za mu koyi tsari game da sanya guntu.