Bari ' s ci gaba da koyon tsari game da guntu wuri.

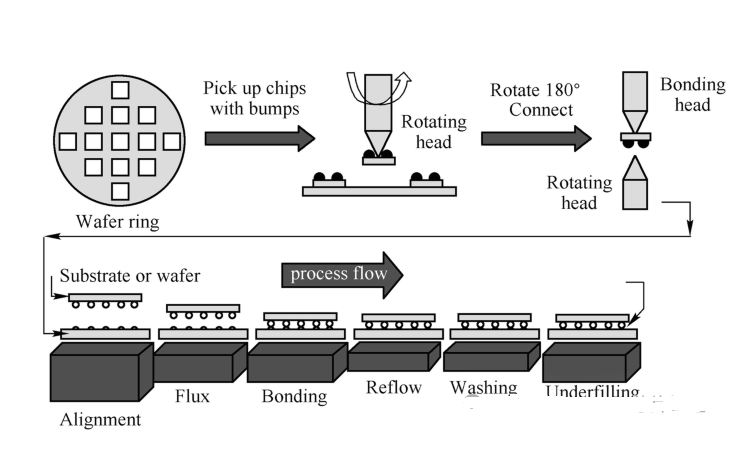

Kamar yadda aka nuna a hoton hoton.

1. Karɓar Chips masu Ciki:

A cikin wannan mataki, an yanka wafern a cikin guntu guda ɗaya, a manne da fim ɗin shuɗi ko fim ɗin UV. Lokacin ɗaukar guntuwar ana buƙatar, fil ɗin suna faɗaɗa daga ƙasa, a hankali suna turawa bayan guntu, ɗaga shi kaɗan. A lokaci guda, injin bututun ƙarfe yana ɗaukar guntu daidai gwargwado daga sama, don haka yana cire guntu daga fim ɗin shuɗi ko fim ɗin UV.

2. Chip Orientation:

Bayan an ɗauko guntu ta hanyar bututun injin, an wuce zuwa ga Boding Head, kuma a lokacin handoff, ana canza yanayin guntu ta yadda gefen da ke da kumbura ya fuskanci ƙasa. shirye don daidaitawa tare da substrate.

3. Daidaita guntu:

Jujjuyawar guntuwar guntu tana daidaita daidai gwargwado tare da pads akan marufi. Daidaiton daidaitawa yana da mahimmanci don tabbatar da cewa kowane kumbura ya daidaita daidai da matsayi na kushin da ke ƙasa. Flux ana amfani da gammaye a kan madaidaicin, wanda ke yin aiki don tsaftacewa, rage tashin hankali a kan ƙwallan solder, da haɓaka kwararar solder.

4. Chip Bonding:

Bayan daidaitawa, guntu ana sanya shi a hankali a kan substrate ta hanyar Bonding Head, sannan kuma aikace-aikacen matsa lamba, zafin jiki, da vibration na ultrasonic, wanda ke haifar da ƙwallan solder don daidaitawa akan substrate, amma wannan haɗin farko ba shi da ƙarfi.

5. Maimaitawa:

Yawan zafin jiki na aikin reflow na narke kuma yana gudana da ƙwallan solder, yana haifar da maƙarƙashiya ta jiki tsakanin guntuwar guntu da madaidaicin madauri. Bayanin yanayin zafin jiki don siyarwar sake kwarara ya ƙunshi preheating, jiƙa, sake kwarara, da matakan sanyaya. Yayin da zafin jiki ke faɗuwa, ƙwallayen solder ɗin da aka narkar da su suna sake dawo da su, suna ƙarfafa haɗin gwiwa sosai tsakanin ƙwallayen siyar da gammaye.

6. Wanka:

Bayan an gama reflow soldering, za a sami ragowar juzu'i mai mannewa saman guntu da ƙasa. Saboda haka, ana buƙatar takamaiman wakili mai tsaftacewa don cire ragowar juyi.

7. Rashin cikawa:

Epoxy resin ko makamancinsa ana allura a cikin tazarar da ke tsakanin guntu da ma'auni. Resin epoxy da farko yana aiki azaman mai ɗaukar hoto don hana fasa a cikin kututturewa saboda yawan damuwa yayin amfani na gaba.

8. Gyara:

Bayan kayan aikin encapsulant ya warke a yanayin da ya dace, ana aiwatar da tsarin gyare-gyaren, sannan kuma gwajin aminci da sauran dubawa, kammala dukkan tsarin ɓoye guntu.

Wannan shine duk bayanan game da guntuwar guntu a dabarar SMT. Idan kuna son ƙarin koyo, kawai ɗauki oda tare da mu.