A yau za mu ci gaba da koyo game da hanya ta uku na kera kayan kwalliyar PCB SMT: Electroforming.

1. Bayanin Ƙa'ida: Electroforming shine mafi hadaddun fasahar kera stencil, wanda ke amfani da tsarin lantarki don gina Layer nickel zuwa kauri da ake buƙata a kusa da ainihin abin da aka riga aka yi, wanda ya haifar da ma'auni daidai wanda ba sa bukatar bayan-aiki don rama girman rami da bangon bangon rami.

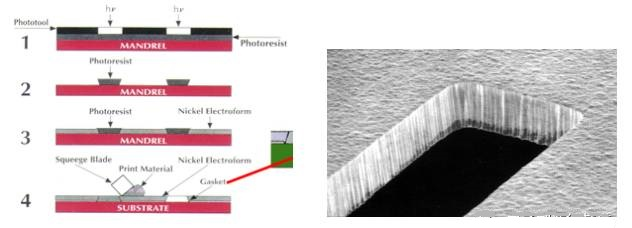

2. Tsari Tsari: Aiwatar da fim ɗin mai ɗaukar hoto zuwa allon tushe → Ƙirƙirar axis na tsakiya {42090} 9408014} Electroplate nickel a kusa da core axis don samar da stencil takardar → Tsaftace → {0109} {4109} 630222} → Tashin ragamar → Kunshin

3. Fe atures: Ganuwar ramin suna da santsi, suna sa ya dace musamman don samar da ƙwanƙwasa mai kyau.

4. Rashin hasashe: Tsarin yana da wuyar sarrafawa, tsarin samar da gurɓatacce ne kuma ba ya dace da muhalli; sake zagayowar samarwa yana da tsayi kuma farashin yana da yawa.

Abubuwan da aka yi amfani da su na lantarki suna da ganuwar rami mai santsi da tsarin trapezoidal, wanda ke ba da mafi kyawun saki na manna. Suna ba da kyakkyawan aiki na bugu don micro BGA, QFP mai ɗorewa, da ƙananan nau'ikan nau'ikan nau'ikan kamar 0201 da 01005. Bugu da ƙari, saboda halayen halayen tsarin tsarin lantarki, an kafa tsinkayar annular dan kadan a gefen rami. , wanda ke aiki azaman "zobe na hatimi" yayin bugu na manna solder. Wannan zobe na hatimi yana taimakawa stencil don manne da kushin ko juriya, yana hana manna solder zubo zuwa gefen kushin. Tabbas, farashin stencil da aka yi tare da wannan tsari kuma shine mafi girma.

A cikin labari na gaba, za mu gabatar da hanyar tsarin Hybrid a cikin PCB SMT stencil.