A yau za mu ci gaba da koyo game da hanya ta ƙarshe na kera PCB SMT stencil: Tsarin Haɓakawa.

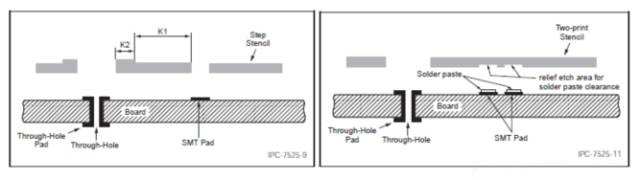

Hybrid tsari dabara, kuma aka sani da mataki stencil kauri tsari, kuma aka sani da mataki stencil kauri tsari. takardar karfe guda ɗaya, wanda ya bambanta da daidaitaccen stencil wanda yawanci yana da kauri ɗaya kawai. Manufar wannan tsari shine don biyan buƙatu daban-daban don ƙarar solder tsakanin sassa daban-daban akan allo. Tsarin masana'anta don stencil na mataki yana haɗa ɗaya ko biyu na dabarun sarrafa stencil da aka ambata a baya don ƙirƙirar stencil guda ɗaya. Gabaɗaya, yawancin masana'antun haɗin gwiwar SMT za su fara amfani da hanyar etching sinadarai don samun kauri da ake buƙata na takardar ƙarfe, sannan amfani da yankan Laser don kammala sarrafa ramukan.

Takalma na mataki sun zo cikin nau'i biyu: Mataki na sama da Mataki-ƙasa. Tsarin masana'antu don nau'ikan nau'ikan biyu shine ainihin iri ɗaya, tare da yanke shawara tsakanin Up da Down dangane da ko yankin da ake tambaya yana buƙatar haɓaka ko raguwa cikin kauri. Idan abubuwan da ake buƙata na haɗuwa don ƙananan kayan haɗin gwal a kan babban allo (kamar CSPs a kan babban allo) suna buƙatar babban adadin solder don yawancin abubuwan da aka gyara, yayin da ake buƙatar rage yawan abin da ake bukata don ƙananan kayan CSP ko QFP. don hana gajerun kewayawa, ko kuma idan ana buƙatar fanko, ana iya amfani da stencil na ƙasa. Wannan ya haɗa da zazzage takardan ƙarfe a wuraren ƙananan abubuwan haɗin gwiwa, yin kauri a cikin waɗannan wuraren ƙasa da sauran wuraren. Akasin haka, don ƴan manyan-filin abubuwan da aka gyara akan allon madaidaicin, gabaɗayan siriri na takardar ƙarfe na iya haifar da ƙarancin adadin manna da aka ajiye akan gammaye, ko don tafiyar da ramuka ta ramuka, babban adadin manna na iya yiwuwa. wani lokaci ana buƙata a cikin ramukan don biyan buƙatun ciko solder a cikin ramukan. A irin waɗannan lokuta, ana buƙatar stencil na mataki-mataki, wanda ke ƙara kauri na takardar karfe a matsayi na manyan pads ko ramuka don ƙara yawan adadin man da aka ajiye. A cikin ainihin samarwa, zabi tsakanin nau'ikan stencils guda biyu sun dogara da nau'ikan da rarraba abubuwan haɗin kan allo.

Na gaba za mu gabatar da matakan gwaji na SMT stencil.