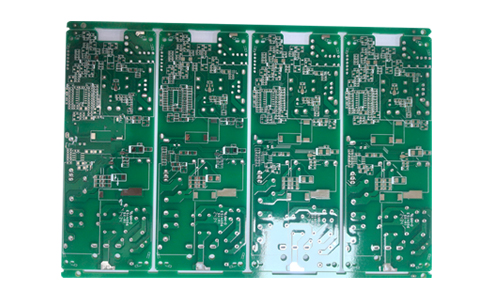

Double PCB mai fesa tin-gefe an tsara shi don sarrafa wutar lantarki da watsa sigina.

Gabatarwar Samfurin PCB Mai Fuskar Tin-Fsashen Wuta Mai Fuskanta

Bayanin samfur

PCB mai fesa tin mai gefe biyu an tsara shi don sarrafa wutar lantarki da watsa sigina. Tsarin kewayawa mai gefe biyu da jiyya mai fesa tin yana ba da kyakkyawan aikin walda da karko, wanda ya dace da kayan wuta daban-daban da na'urorin lantarki.

Abubuwan Samfur

1.Kira mai gefe biyu

2. An karɓi shimfidar da'ira mai gefe biyu don sauƙaƙe haɗaɗɗun haɗin da'ira da haɓaka sassauƙar ƙira da ƙanƙanta.

3.Tin-sprayed surface treatment

4.Tin-sprayed (HASL) tsari an karbe shi don samar da kyakkyawan walda da aiki mai kyau, wanda ya dace da yawancin hanyoyin walda.

5.Kyakkyawan aikin lantarki

6. Ƙirƙirar ƙira yana tabbatar da amincin sigina, dace da aikace-aikace tare da manyan buƙatu don iko da ingancin sigina.

7.Kyakkyawan aikin kawar da zafi

8. Dace da aikace-aikace masu ƙarfi, zai iya rage yawan zafin jiki na kewayawa yadda ya kamata kuma inganta kwanciyar hankali da amincin tsarin.

9.Durability

10. Ana amfani da kayan aiki masu inganci, tare da juriya mai kyau da juriya na oxidation, dace da yanayin muhalli daban-daban.

Yankunan aikace-aikace

Gudanar da wutar lantarki

Ya dace da tsarin sarrafa wutar lantarki kamar sauya kayan wuta da masu sauya DC-DC.

Kayan aikin masana'antu

Ana amfani da shi sosai a cikin sarrafa masana'antu, kayan aiki na atomatik da sauran fannoni.

Kayan aikin sadarwa

Ya dace da kayan aikin sadarwa mai girma kamar tashoshi na tushe da tsarin sadarwa.

Kayan lantarki na masu amfani

Samar da ingantaccen goyan bayan wutar lantarki a cikin samfuran kayan lantarki masu inganci.

Bayanan fasaha

| Adadin yadudduka | mai gefe biyu | Mafi ƙarancin buɗe ido | 0.2 mm |

| Kaurin jan karfe | 1 oz | Nisa mafi ƙarancin layi | 0.1 mm |

| Kayan allo | FR-4 KB6160 | Maganin saman | HASL |

| Launin abin rufe fuska mai solder | koren mai mai farin rubutu |

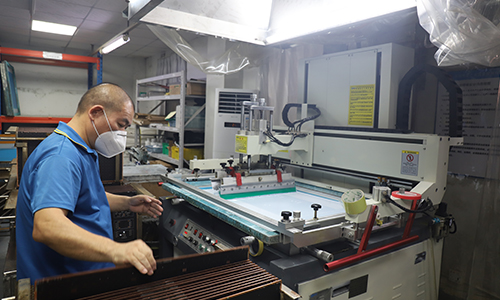

Tsarin samarwa

1.Zane-zane

2.Yi amfani da ƙwararriyar ƙira ta PCB don ƙira da shimfidawa.

3. Zabin kayan aiki

4.Zaɓi madaidaicin madauri da kaurin jan ƙarfe bisa ga bukatun abokin ciniki.

5.Manufar sarrafawa

6.Yi matakai kamar photolithography, etching, drilling, da lamination.

7. Maganin saman

8.Yi amfani da tsarin HASL don maganin saman ƙasa don tabbatar da ingantaccen solderability da haɓakawa.

9.Matsalar gwaji

10.Yi gwaje-gwajen lantarki da gwaje-gwajen aminci don tabbatar da ingancin samfur.

11. Lokacin bayarwa

12. Bayan kammalawa, shirya da jigilar kaya don tabbatar da cewa samfurin ya isa ga abokin ciniki lafiya.

|

|

Ƙarshe

PCB mai fesa wuta mai gefe biyu shine kyakkyawan zaɓi don mafita mai ƙarfi kuma ya dace da nau'ikan kayan wuta da na'urorin lantarki. Tare da ingantaccen aikin sa na lantarki, ikon waldawa da dorewa, zai iya cika ƙaƙƙarfan buƙatun na'urorin lantarki na zamani don samar da wutar lantarki.

FAQ

1.Q: Yaya nisa masana'antar ku daga filin jirgin sama mafi kusa?

A: Kimanin kilomita 30

2.Q: Menene mafi ƙarancin odar ku?

A: Guda ɗaya ya isa yin oda.

3.Q: Wadanne al'amurran walda na yau da kullun ake fuskanta wajen kera PCB, kuma ta yaya za'a warware su?

A: Abubuwan al'amuran walda na gama gari sun haɗa da gaɓoɓin solder da ke damuwa, solder mai sanyi, gadar solder, da rashin isasshen jika na pads. Ana iya warware waɗannan ta haɓaka bayanan martabar zafin jiki na sake kwarara ko siyar da igiyar ruwa, ta amfani da ingantaccen solder, da tabbatar da girman kushin da ya dace yayin lokacin ƙira.

4.Q: Yaya tsawon lokacin ake ɗauka don sadar da PCB mai girma na HDI?

A: Muna da kayan kaya (kamar RO4350B, RO4003C, da dai sauransu), kuma lokacin bayarwa mafi sauri zai iya zama kwanaki 3-5.