Tare da saurin haɓaka sabbin fasahar abin hawa makamashi, aikace-aikacen da aka haɗa da tsarin a cikin sabbin motocin makamashi ya zama mafi girma.

Sabbin Motocin Makamashi PCB Gabatarwar Samfurin

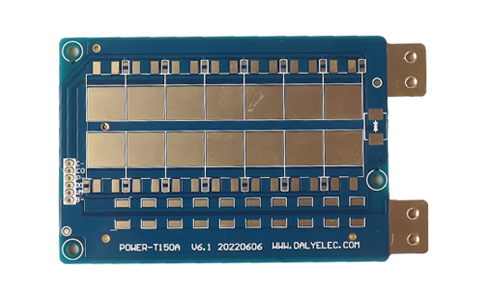

Tare da saurin haɓaka sabbin fasahar abin hawa makamashi, aikace-aikacen da aka saka a cikin sabbin motocin makamashi ya ƙara ƙaruwa. A matsayin ainihin abin da ke tattare da jan ƙarfe, toshe sabon motar makamashi PCB (Hukumar da'ira) tana ɗaukar ayyuka masu yawa kamar sarrafawa, sadarwa da sarrafa wutar lantarki. Mai zuwa shine cikakken bayani game da katangar jan karfe na sabon samfurin PCB abin hawa makamashi.

|

|

1. Bayanin Samfura

Sabuwar toshewar jan ƙarfe da aka haɗa da sabuwar motar makamashi PCB babban kwamiti ne da aka tsara don sabbin motocin makamashi, yana haɗa nau'ikan ayyuka da yawa kamar tsarin sarrafa baturi (BMS), mai sarrafa mota, caja kan allo da kan- tsarin infotainment jirgin. Wannan PCB yana da mafi kyawun aikin watsar zafi da ƙarfin ɗaukar nauyi ta hanyar fasahar toshe tagulla, kuma yana iya aiki da ƙarfi a cikin hadadden mahalli na mota.

2. Abubuwan Samfur

2.1 Babban Dogara

Yin amfani da ingantattun gyare-gyare da gyare-gyaren masana'antu na ci gaba yana tabbatar da amincin PCBs a cikin wurare masu zafi kamar zafi mai zafi, zafi mai zafi da kuma girgizar kasa.

2.2 Kyawawan Ayyukan Rage Zafi

Fasahar toshe tagulla da aka haɗa tana haɓaka ƙarfin zafi na PCB don daidaitawa da buƙatun ƙarfin sabbin motocin makamashi.

2.3 Babban Ƙarfin ɗauka na Yanzu

Tushen jan ƙarfe da aka haɗa zai iya ɗaukar mafi girman halin yanzu, rage yawan da'ira na yanzu, da haɓaka aikin tsarin gaba ɗaya.

2.4 Babban ikon hana tsangwama

Ta hanyar ƙira mai yawa da fasaha na garkuwa, ana inganta ƙarfin tsoma baki na PCB don tabbatar da daidaito da daidaiton watsa sigina.

2.5 Babban haɗin kai

Haɗa nau'ikan ayyuka da yawa yana rage sarƙaƙƙiya da ƙarar tsarin kuma yana haɓaka aikin gabaɗaya da amincin tsarin.

3. Ma'aunin Fasaha

| Adadin yadudduka | 3 | Mafi qarancin faɗin layi da tazarar layi | 0.8/0.8MM |

| Kaurin allo | 3.0mm | Mafi ƙarancin buɗe ido | 1.2 |

| Kayan allo | FR4+ jan karfe substrate | Maganin saman | 2u immersion zinariya |

| Kaurin jan karfe | 2OZ na ciki da na waje yadudduka | Matsayin tsari | abin da aka saka tagulla |

4. Yankunan aikace-aikace

4.1 Tsarin Gudanar da Baturi (BMS)

Ana amfani dashi don saka idanu da sarrafa matsayin baturin baturin don tabbatar da aminci da ingantaccen aiki na baturin.

4.2 Mai sarrafa Mota

Ana amfani dashi don sarrafa aikin motar da samar da ingantaccen wutar lantarki da ayyukan dawo da makamashi.

4.3 Caja a kan allo

Ana amfani dashi don canza ƙarfin waje zuwa ƙarfin lantarki da halin yanzu wanda ya dace da cajin baturi, yana tallafawa caji mai sauri da ayyukan caji mai wayo.

4.4 Tsarin infotainment na cikin mota

Ana amfani dashi don samar da ayyuka kamar kewayawa, nishaɗi da sadarwa, da haɓaka ƙwarewar tuƙi da jin daɗin fasinja.

4.5 Tsarin sarrafa jiki

Ana amfani da shi don sarrafa ayyukan jiki kamar fitilu, kwandishan, makullin ƙofa, da sauransu, don inganta matakin hankali na abin hawa.

5. Tsari Mai Sarrafa

5.1 Zane-zane

Yi amfani da kayan aikin EDA don ƙira da hanyoyin da'irori don tabbatar da hankali da amincin da'ira.

5.2 Zaɓin Abu

Zaɓi madaidaitan ma'auni da foils na jan karfe don tabbatar da aiki da amincin PCB.

5.3 Etching

Yi etching don samar da tsarin da'ira.

5.4 Ta hanyar

Hana ramuka da yin electroplating don samar da ta hanyar.

5.5 Lamination

Laminate manyan yadudduka na foil na tagulla tare da kayan aiki don samar da PCB mai yawan Layer.

5.6 Tubalan tagulla

Sanya tubalan jan karfe a mahimman wurare don inganta ɓarkewar zafi da ƙarfin ɗauka na yanzu.

5.7 Maganin Sama

Yi jiyya ta sama kamar HASL, ENIG, da sauransu don inganta aikin walda da juriya na PCBs.

5.8 Welding

Abubuwan walda don kammala taro.

5.9 Gwaji

Yi gwajin lantarki da na aiki don tabbatar da ingancin samfur.

6. Kula da inganci

6.1 Duban Kayan Kayan Kayan Kayan Kayan Gida

Tabbatar da cewa ingancin ma'auni da foils na jan karfe sun dace da ma'auni.

6.2 Sarrafa Tsarin Kerawa

Sarrafa sosai kowane tsari don tabbatar da daidaito da amincin samfur.

6.3 Gwajin samfurin da aka gama

Gwajin aikin lantarki, gwajin aiki da gwajin muhalli ana aiwatar da su don tabbatar da cewa samfurin ya cika buƙatun ƙira.

|

|

7. Kammala

Haɗe-haɗe na jan ƙarfe sabon motar makamashi PCB ana amfani dashi sosai a cikin tsarin sabbin motocin makamashi daban-daban saboda babban amincinsa, kyakkyawan aikin watsar da zafi da babban ƙarfin ɗaukar nauyi na yanzu. Ta hanyar ƙira mai ma'ana da tsauraran tsarin masana'antu, ingantaccen ingantaccen samar da wutar lantarki da hanyoyin sarrafawa za a iya samu don biyan buƙatu daban-daban na sabbin motocin makamashi.

Ina fata wannan gabatarwar samfurin zai taimaka muku!

FAQ

1.Q: Yaushe zan iya samun tsokaci bayan na samar da Gerber, bukatun tsarin samfur?

A: Ma'aikatan tallace-tallacen mu za su ba ku magana a cikin awa 1.

2.Q: Ma'aikata nawa kuke da su a masana'antar ku?

A: Fiye da 500.

3.Q: Yadda za a warware matsalar daidaitawar interlayer a cikin kera PCB na mota?

A: Kurakurai na kuskuren tsaka-tsaki yawanci ana haifar da su ta rashin ingantattun tsarin sakawa kuma ana iya warware su ta hanyar inganta daidaiton matsayi.

4.Q: Shin kamfanin ku yana da daidaitaccen tsarin takaddun shaida mai alaƙa da masana'antar kera motoci?

A: Mun mallaki takardar shedar EU IATF16949.