Babban iko mai ƙarfi na zinariya yatsa mai ƙarfi na PCB allon kewayawa shine allon kewayawa da yawa wanda aka tsara musamman don samar da wutar lantarki mai ƙarfi.

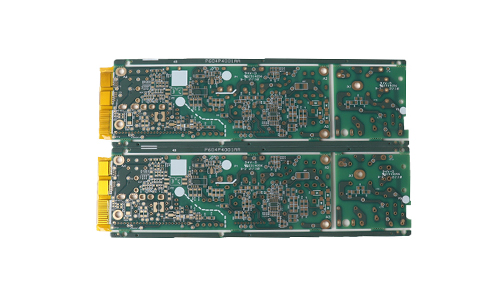

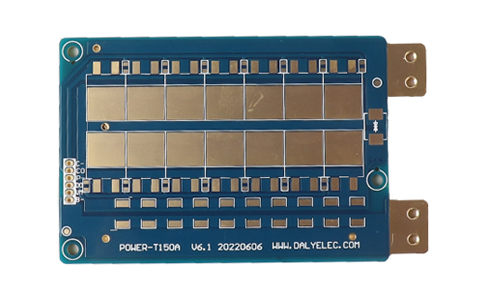

4-Layer High Power Goldfinger Power Supply PCB Samfurin Gabatarwa

Babban iko mai ƙarfi na zinari huɗu na PCB allon kewayawa shine allon kewayawa mai yawa wanda aka kera musamman don samar da wutar lantarki mai ƙarfi. Yana da high conductivity, m zafi dissipation yi da babban abin dogara. Ana amfani da wannan allon kewayawa na PCB sosai a cikin sabobin, cibiyoyin bayanai, tulin cajin abin hawa na lantarki, samar da wutar lantarki da sauran fagage. Mai zuwa shine cikakken gabatarwar ga samfurin allon kewayawa na PCB mai ƙarfi mai ƙarfi mai ƙarfi na zinari.

|

|

1. Bayanin Samfura

Babban iko mai ƙarfi na zinari mai ƙarfi na PCB allon kewayawa mai Layer huɗu yana ɗaukar ƙirar tsari mai Layer huɗu, haɗe tare da fasahar yatsan zinare, don samar da ingantaccen watsawa na yanzu da kyakkyawan aikin hulɗa. Kwamitin da'ira na PCB na iya aiki a tsaye a cikin yanayi mai tsauri kamar zafin jiki mai zafi, zafi mai zafi da girgiza mai ƙarfi, yana tabbatar da aminci da tsawon rayuwar tsarin wutar lantarki.

2. Abubuwan Samfur

2.1 Babban aiki mai ƙarfi

Yin amfani da ingantaccen foil na jan karfe da fasahar yatsa na zinari, yana ba da kyawawan kaddarorin gudanarwa kuma yana tabbatar da ingantaccen watsa babban ƙarfin halin yanzu.

2.2 Kyakkyawan aikin zubar da zafi

Ta hanyar zane-zane mai yawa da kuma hanyoyin watsar da zafi mai ma'ana, ƙarfin watsar da zafi na PCB yana da mahimmanci don saduwa da bukatun samar da wutar lantarki mai ƙarfi.

2.3 Babban Aminci

Ana amfani da na'urori masu inganci da ci-gaba na masana'antu don tabbatar da amincin PCBs a cikin yanayi mara kyau kamar zafin jiki mai zafi, zafi mai zafi, da rawar jiki.

2.4 Babban ikon hana tsangwama

Ta hanyar ƙirar da'ira mai ma'ana da fasaha na kariya, ana inganta ƙarfin tsoma bakin PCB na anti-electromagnetic don tabbatar da kwanciyar hankali da amincin tsarin wutar lantarki.

2.5 Babban haɗin kai

Ƙirar nau'i-nau'i huɗu na iya cimma haɗin kai mafi girma, rage rikitarwa da ƙarar tsarin, da kuma inganta aikin gaba ɗaya da amincin tsarin.

3. Ma'aunin Fasaha

| Adadin yadudduka | 4 | Mafi qarancin faɗin layi da tazarar layi | 0.3/0.3MM |

| Kaurin allo | 1.6mm | Mafi ƙarancin buɗe ido | 0.3 |

| Kayan allo | KB-6160 | Maganin saman | zinare nutsewa + zinare 30U |

| Kaurin jan karfe | ciki da waje yadudduka 2OZ | Matsayin tsari | Babu ragowar gubar + a shafa manne mai zafi mai zafi |

4. Yankunan aikace-aikace

4.1 Sabar

Ana amfani da shi don sarrafa kewayawa da watsa wutar lantarki na tsarin wutar uwar garke, yana samar da babban abin dogaro da manyan hanyoyin samar da wutar lantarki.

4.2 Cibiyar Bayanai

Ana amfani da shi don sarrafa kewayawa da watsa wutar lantarki na tsarin wutar lantarki don tabbatar da ingantaccen jujjuyawar wutar lantarki da ingantaccen fitarwa.

4.3 Cajin motocin lantarki

Ana amfani da shi don sarrafa kewayawa da watsa wutar lantarki na cajin abin hawa, yana samar da ingantaccen aminci da mafita na samar da wutar lantarki na tsawon rai.

4.4 Kayan wutar lantarki na masana'antu

Ana amfani da shi don sarrafa kewayawa da watsa wutar lantarki na tsarin wutar lantarki don tabbatar da kwanciyar hankali da amincin tsarin.

4.5 Sauran kayan wuta mai ƙarfi

Ana amfani dashi don sarrafa kewayawa da watsa wutar lantarki na sauran kayan wuta mai ƙarfi, kamar kayan wuta na UPS, inverters, da sauransu.

5. Tsari Mai Sarrafa

5.1 Zane-zane

Yi amfani da kayan aikin EDA don ƙira da wayoyi don tabbatar da hankali da amincin kewaye.

5.2 Zaɓin kayan aiki

Zabi ingantattun kayan aiki da foil na jan karfe don tabbatar da aikin PCB da aminci.

5.3 Etching

Ana yin etching don samar da tsarin da'ira.

5.4 Ta hanyar

Hana ramuka da farantin su don samar da ta hanyar.

5.5 Lamination

Yadudduka huɗu na foil ɗin tagulla an lakafta su tare da kayan tushe don samar da PCB mai Layer huɗu.

5.6 Maganin saman

Gudanar da jiyya ta sama, kamar HASL, ENIG, da sauransu, don inganta aikin walda da juriya na PCB.

5.7 Goldfinger

Ana yin aikin sarrafa yatsan zinari don tabbatar da kyakkyawan aikin tuntuɓar juna da juriya.

5.8 Welding

Sayar da kayan aikin kuma kammala taron.

5.9 Gwaji

Gudanar da gwaje-gwajen lantarki da na aiki don tabbatar da ingancin samfur.

6. Kula da inganci

6.1 Binciken albarkatun kasa

Tabbatar da ingancin ma'auni da foil na jan karfe sun dace da ma'auni.

6.2 Gudanar da tsarin sarrafawa

Sarrafa sosai kowane tsari don tabbatar da daidaiton samfur da amincin.

6.3 Gwajin samfurin da aka gama

Gudanar da gwajin aikin lantarki, gwajin aiki da gwajin muhalli don tabbatar da cewa samfuran sun cika buƙatun ƙira.

|

|

7. Kammala

Na'ura mai ƙarfi mai ƙarfi na zinari huɗu na PCB ana amfani dashi sosai a cikin manyan tsarin samar da wutar lantarki daban-daban saboda haɓakar ƙarfinsa, kyakkyawan aikin watsar da zafi da babban abin dogaro. Ta hanyar ƙira mai ma'ana da tsauraran matakai na masana'antu, ingantattun hanyoyin samar da wutar lantarki za a iya cimma su don biyan bukatun tsarin wutar lantarki daban-daban.

Fata wannan gabatarwar samfurin zai taimaka muku!

FAQ

Tambaya: Yaya nisa masana'antar ku daga filin jirgin sama mafi kusa?

A: Kimanin kilomita 30

Tambaya: Menene mafi ƙarancin odar ku?

A: Guda ɗaya ya isa yin oda.

Tambaya: Yadda ake warware gajerun da'irori da buɗaɗɗen da'irori a cikin PCB mai ƙarfi?

A: Gajerun da'irori da buɗaɗɗen da'irori galibi suna faruwa ne sakamakon tsufa na da'ira ko lahani na masana'antu, kuma suna buƙatar warwarewa ta hanyar dubawa da kyau da hanyoyin gyara ƙwararru.

Tambaya: Kuna da injunan hakowa Laser?

A: Muna da injin hakowa na Laser mafi ci gaba a duniya.